We deliver the best quality Cement contributing to the growth and development of infrastructure in India.

Get Free QuotationWe deliver the best quality Cement contributing to the growth and development of infrastructure in India.

Get Free Quotation

CEMENTING BONDS WITH OUR CUSTOMERS... Purbanchal Cement Limited is one of the most coveted Group of Companies in Eastern India, having an Integrated Cement Manufacturing Unit at Sonapur, Kamrup (Assam).

We deliver the best quality Cement contributing to the growth and development of infrastructure in India, individuals, commercial and others with their consistent quality and services.

Discover MeWe deliver the best quality Cement contributing to the growth and development of infrastructure in India, individuals, commercial and others with their consistent quality and services

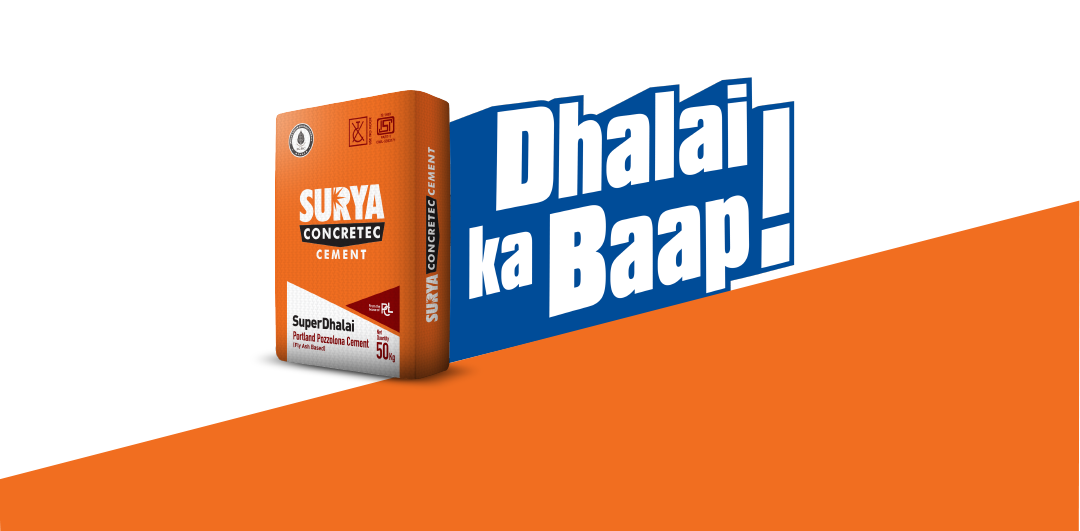

Surya Cement produces high-quality cement that meets or exceeds industry standards.

Surya Cement offers competitive prices on all cement and concrete products.

Surya Cement has 20+ years of experience in the industry and has a reputation for producing efficient and quality products.

Surya Cement continuously invest and research on new technology to improve the quality and efficacy of the cement it produces.

We have dedicated customer service team that is available to assist customers for their needs.

Feel free to contact us!